Study Electrical and Electronics Engineering Online

Study Electrical is an Online Electrical Engineering Learning Site. We provide courses, articles and study materials to learn Electrical and Electronics Engineering.

Latest Posts

Popular Posts

Courses

- RealParsProgrammable Logic Controller (PLC) Basic Course10 WeeksAll levels13 Lessons0 Quizzes21107 StudentsFree

- AdelGastliElectrical Machines for Undergraduates10 WeeksAll levels30 Lessons0 Quizzes32527 StudentsFree

- Khan AcademyIntroduction to electrical engineeringLifetimeAll levels7 Lessons0 Quizzes9567 StudentsFree

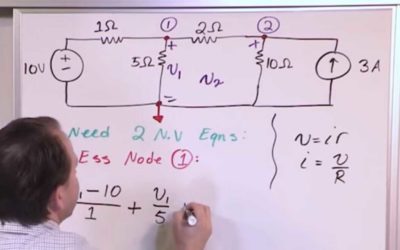

- TeslaEngineering Circuit Analysis for Beginners10 WeeksAll levels20 Lessons0 Quizzes171 StudentsFree